CORMASTER® SANDWICH PANELS

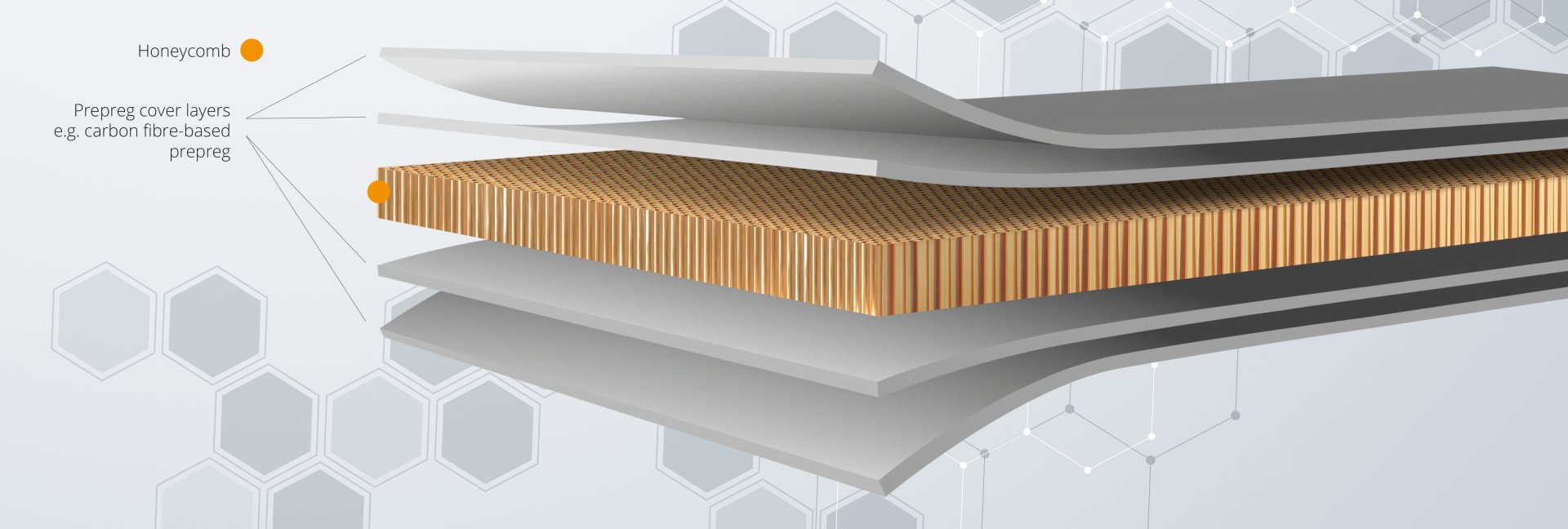

As the name indicates, sandwich panels consist of several layers of material. Usually, the panels are comprised of two thin outer layers that are firmly bonded to an inner core. On account of this structure, sandwich panels are also known as composite panels.

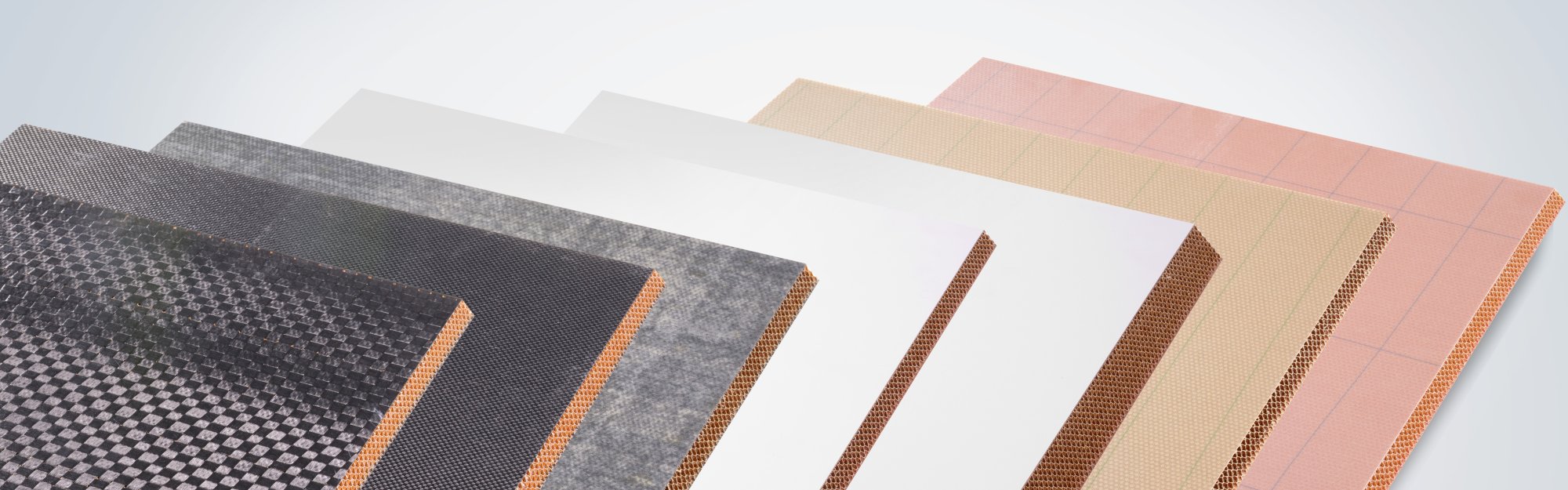

Different types of sandwich panels

SCHÜTZ manufactures sandwich panels in a wide variety of designs according to individual customer specifications, ranging from flat sandwich panels made in our multi-level presses to autoclave-cured curved panels. Depending on the customer’s specifications, we supply both panel types as semi-finished products or as finished engineered panels cut to size on the basis of the customer’s drawings including all additional and integral parts such as inserts.

Material & Applications

All SCHÜTZ sandwich panels are based on a CORMASTER® honeycomb core – a high-performance honeycomb material developed and manufactured by SCHÜTZ. Prepregs based on glass fibre or carbon fibre with a phenolic or epoxy resin system are used as top layers for the sandwich panels. The panels, which have an extremely low weight combined with outstanding fire properties (FST), meet the highest mechanical requirements. Light – Strong – Robust. These characteristics make our honeycomb sandwich panels the ideal material for a wide range of applications.

Further applications of our CORMASTER® sandwich panels can be found in the military sector, medical technology and in general mechanical engineering.