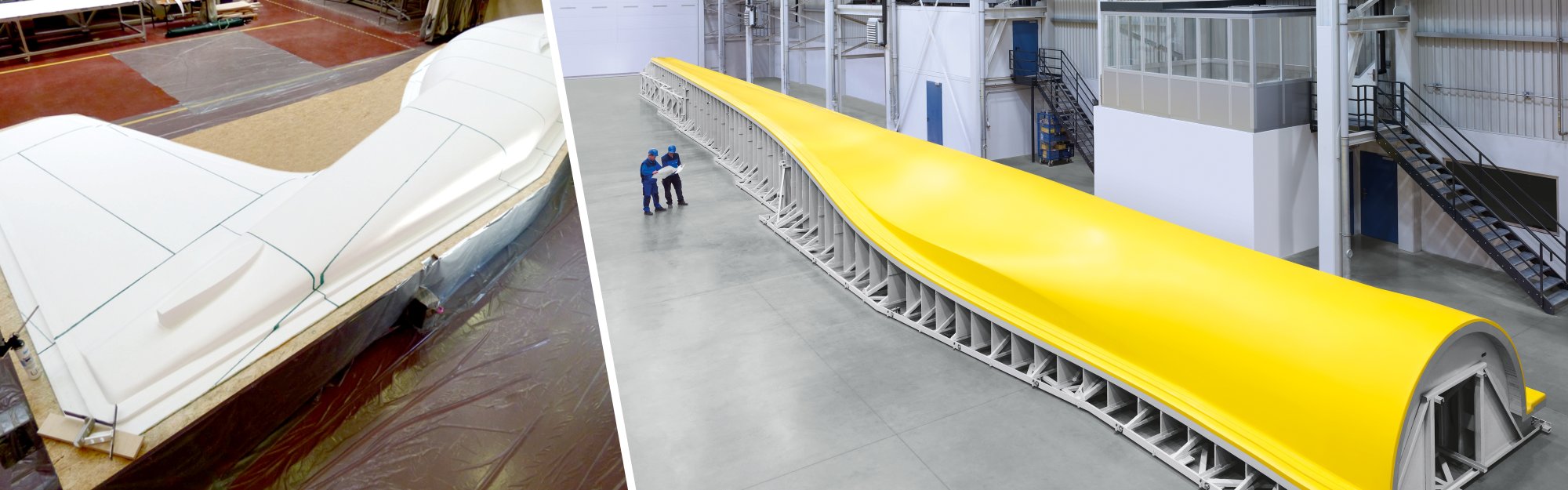

The precise machining of wood and plastic is carried out at SCHÜTZ COMPOSITES using a 5-axis milling machine. This is also suitable for very large components thanks to its dimensions of 56 m x 8.5 m x 4.5 m and the two portals that work in parallel.

The short process paths from model construction through to mould making ensure highly efficient working practices. In the interests of simplifying the transportation process, large constructions are designed in sections and then subsequently aligned and connected using laser measurement processes.

Along the different quality gates implemented at SCHÜTZ COMPOSITES, we check and ensure the degree of curing, vacuum integrity and contour accuracy throughout the production process in accordance with the very highest standards.