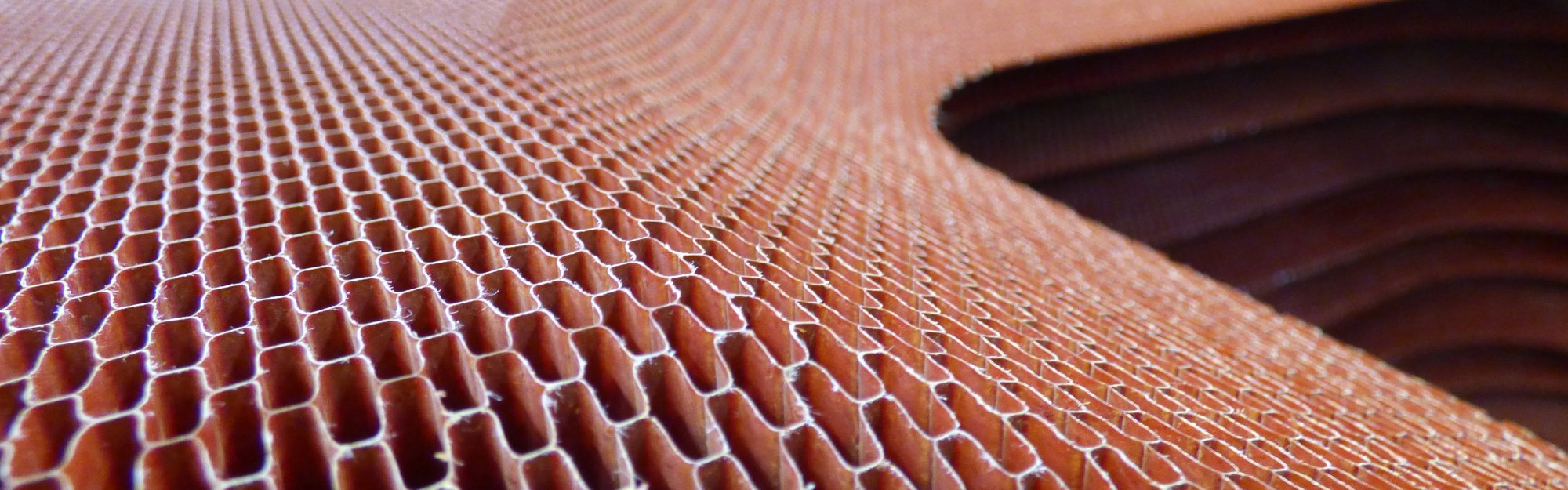

SCHÜTZ, a leading manufacturer of lightweight, aramid paper-based materials, produces more than just honeycomb cores and honeycomb panels. As a built-to-print supplier and working in close coordination with our customers, we also offer CORMASTER® aramid honeycomb cores in prefabricated variants. Using specialized processing methods and state-of-the-art equipment, we manufacture complete honeycomb core sub-structures that can be seamlessly integrated into our customers’ projects.

Which processes can be used to shape our CORMASTER® honeycomb cores to our customers’ individual specifications?

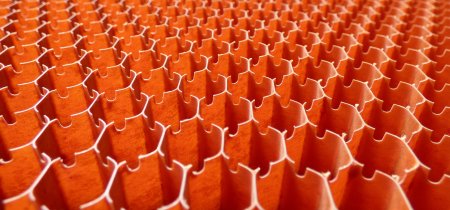

For the customized production of finished components and substructures, we can draw on our complete product range: our high-performance lightweight material CORMASTER® is available in material types C1, C2 and CN1 and consists of a variety of NOMEX® and KEVLAR® specialty papers from DuPontTM in combination with special phenolic resins. The aramid honeycomb core is optimally configured for the specific application – with hexagonal or overexpanded cells in widths from 3.2 mm to 9.6 mm and a density from 20 kg/m3 to 144 kg/m3. Multiple honeycomb types can also easily be combined in one component.

SCHÜTZ manufactures honeycomb panels and honeycomb blocks in a wide variety of customized configurations. We can offer the ideal construction material for almost all applications. Sometimes, the ideal solution for a specific application is a combination of different honeycomb types.

For these purposes, SCHÜTZ offers a choice of products, e.g. bonded honeycomb cores. Especially in three-dimensionally curved components that are exposed to high mechanical loads, it is crucial that the honeycombs do not collapse during draping into the final geometry and that the outstanding mechanical properties are retained. For this reason, SCHÜTZ offers thermoformed honeycombs that are thermally shaped using a very gentle process. The honeycomb structure remains intact and stable. These formed honeycombs can then be shaped to the required geometry by 3-dimensional milling to further optimize the accuracy of the fit.

Thermally formed and milled core materials are used, for example, in:

Brazed honeycombs are used, for example, in:

Flat milled core materials are used, for example, in: