CORMASTER® THE HIGH-TECH LIGHTWEIGHT

MATERIAL FROM SCHÜTZ.

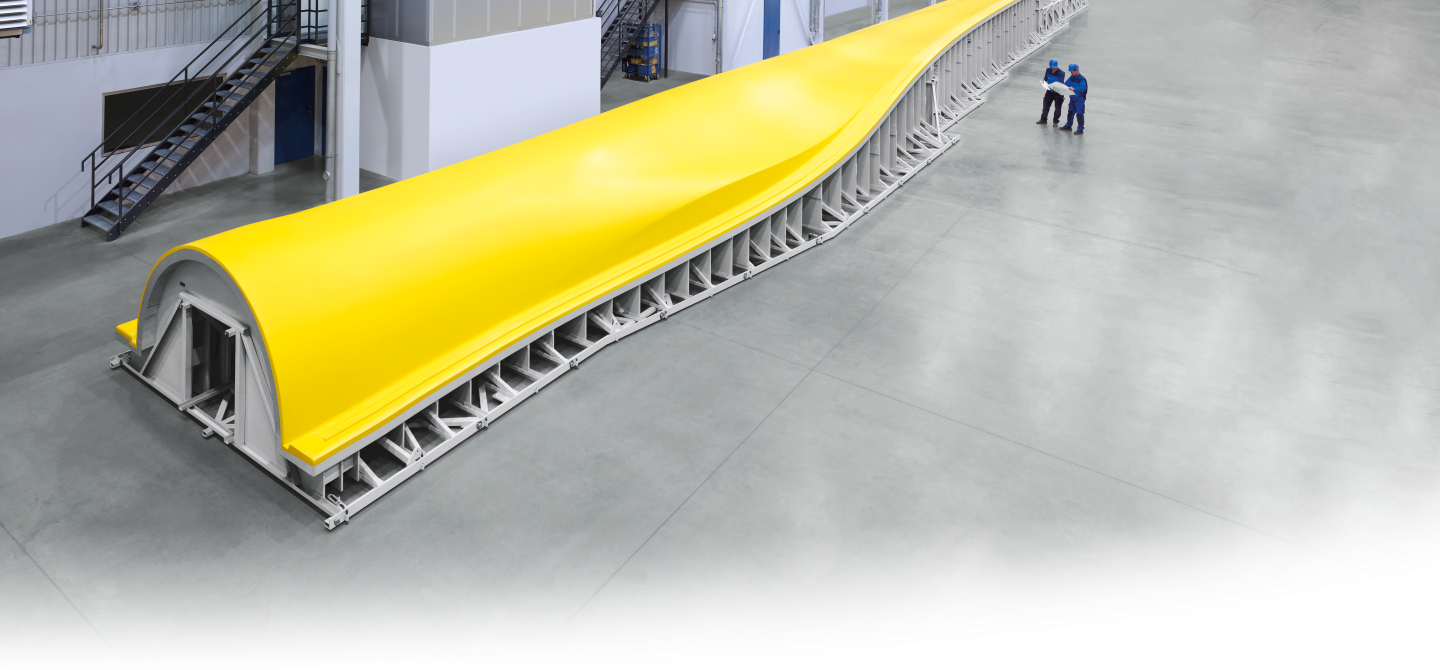

Under the CORMASTER® brand, the company has for more than three decades produced lightweight honeycomb materials and fibre composites, which are used in a wide range of applications, including the aerospace industry. CORMASTER® Honeycombs are available as entire block, sawed sheets or engineered parts, e.g. as milled structure or sandwich panel.

In accordance with your exact individual specifications we shape CORMASTER® honeycomb blocks using various certified processes, including milling and heat-shaping. You get the honeycombs in precisely the shape you need – for example as core material for your individual application.

For aircraft cabin / interior applications we offer standard panels and develop and produce three-dimensional, autoclave-cured sandwich panels as well as complete sub-structures, based on the geometric data of the components you need. For the manufacturing and hardening we operate several multi-level sandwich presses as well as a large-capacity autoclave.

In close cooperation with you, our skilled engineers manufacture all the necessary moulds for your products in our own model and mould-making department, based on the geometric data of the components you need.